Hard Coated Polycarbonate for scratch resistance

Best Hard Coated Polycarbonate with Scratch Resistance

Hard Coated Polycarbonate Introduction

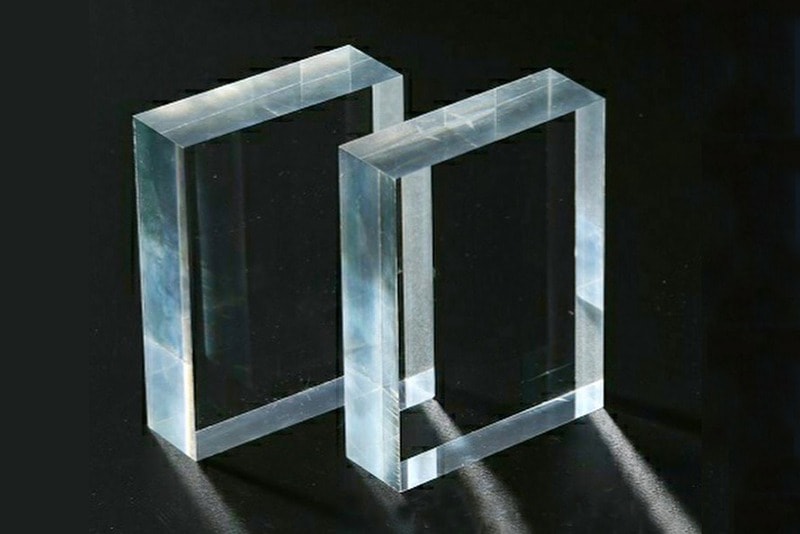

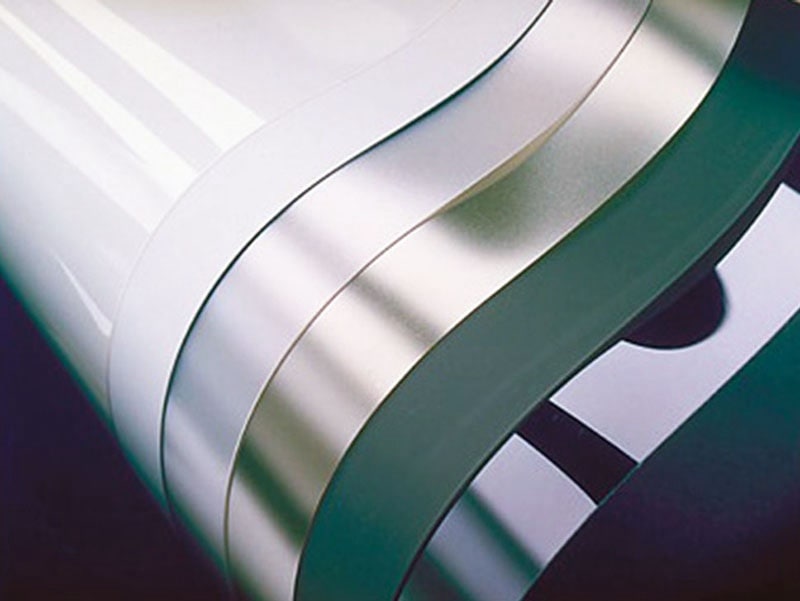

Hard Coated Polycarbonate is an enhanced polycarbonate sheet in the hardness of two surfaces. It can increase the surface hardness for 2-6 levels than the general-purpose polycarbonate sheets. The lifespan will be increased highly under the abrasion environment. As the leading supplier of hard-coated polycarbonate sheets in China, UVPLASTIC provides standard and custom hard-coated polycarbonate sheets for global clients. The standard surface hardness is HB under 750g testing weight. And the custom hard-coated polycarbonate offers a surface hardness up to 4H under 750g testing weight. In this case, clients can choose a suitable product for specific applications with high cost-efficiency.

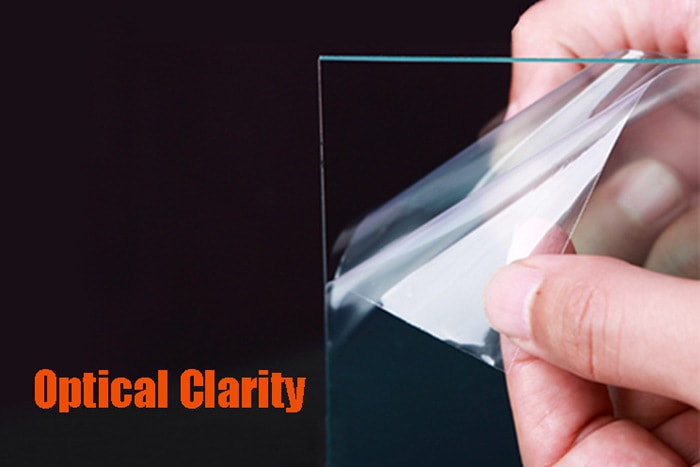

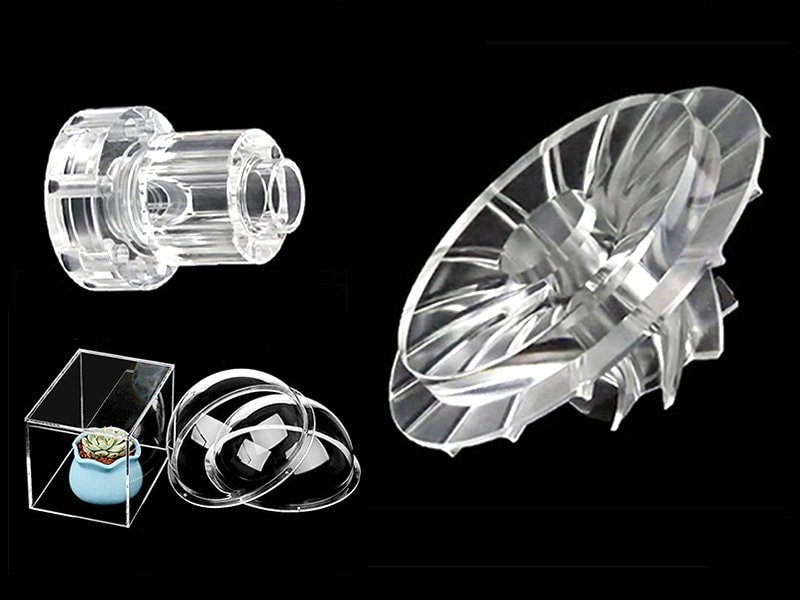

UVFPC-HC is the model of UVPLASTIC Hard Coated Polycarbonate sheets, which offers excellent performances in abrasion resistance, anti-scratch, and chemical resistance under indoor and outdoor environments. Meantime, it offers excellent optical clarity. Therefore it is very effective for good visibility for some applications, like motorcycle windshield, machinery safety shield, polycarbonate face shield, and eye protection equipment, window with bullet-proof function in the bank, outdoor signs, specialty vehicle glazing, etc.

Hard Coated Polycarbonate Sheet Specification

Standard size

| Thickness (mm) | Width (mm) | Length (mm) | Pencil Hardness |

|---|---|---|---|

| 1mm, 1.5mm, 2mm, 2.5mm, 3mm | 915mm, 1000mm, 1220mm | 1000mm, 1220mm, 2400mm | HB, H, 2H, 3H, 4H, 6H |

| 4mm, 5mm, 6mm, 8mm | 1000mm, 1220mm | 2000mm, 2400mm | HB, H, 2H, 3H, 4H, 6H |

| 10mm, 12mm, 15mm, 20mm | 1000mm | 2000mm | HB, H, 2H, 3H, 4H, 6H |

Products Range

| Model | Description |

|---|---|

| UVFPC-HC-HB | Hard coated on one or both sides, the pencil hardness is HB; |

| UVFPC-HC-2H | Hard coated on one or both sides, the pencil hardness is 2H; |

| UVFPC-HC-3H | Hard coated on one or both sides, the pencil hardness is 3H; |

| UVFPC-HC-4H | Hard coated on one or both sides, the pencil hardness is 4H; |

| UVFPC-HC-5H | Hard coated on one or both sides, the pencil hardness is 5H; |

Testing Process Video

Physical Properties

| Physical Properties | Test Condition | Standard Value | Unit | Test standard |

|---|---|---|---|---|

| Density | 1.2 | g/cm3 | ISO 1183 | |

| Pencil Hardness | 750 g | HB, H, 2H, 3H, 4H | ASTM D3363 | |

| Abrasion Resistance | 0000# steel wool, with 250 g/cm2 pressure, 5 cm stroke reciprocating for 25 times | No Damage | ||

| Hot Water Resistance | 80°C (hot water) × 10 min | No Change | ||

| Moisture Resistance | 70°C × 80% RH × 48h | No Change | ||

| Heat Resistance | 80°C×40min | No Change | ||

| Low Temperature Resistance | -30°C×10h | No Change | ||

| Cold & Heat Cycle Test | From -30°C to 23°C (9h) | No Change | ||

| Adhesion | Cross-hatching test 3M tape (5 times) | No Detaching | ||

| Tensile Strength | 60 | MPa | ISO 527 | |

| Flexural Strength | 85 | MPa | ISO 178 | |

| Ethanol Resistance, Weak Acid Resistance (0.5%) Salt Water Resistance | Coated sample hardening layer wiped with absorbent cotton ball fully immersed in test solution, then sealed with PE film, left at room temperature for 24 h, rinsed with water, then observation. | No Change | ||

| Haze | <0.5 | % | ASTM D1003 | |

| Transmittance | ≥90 | % | ASTM D1003 |

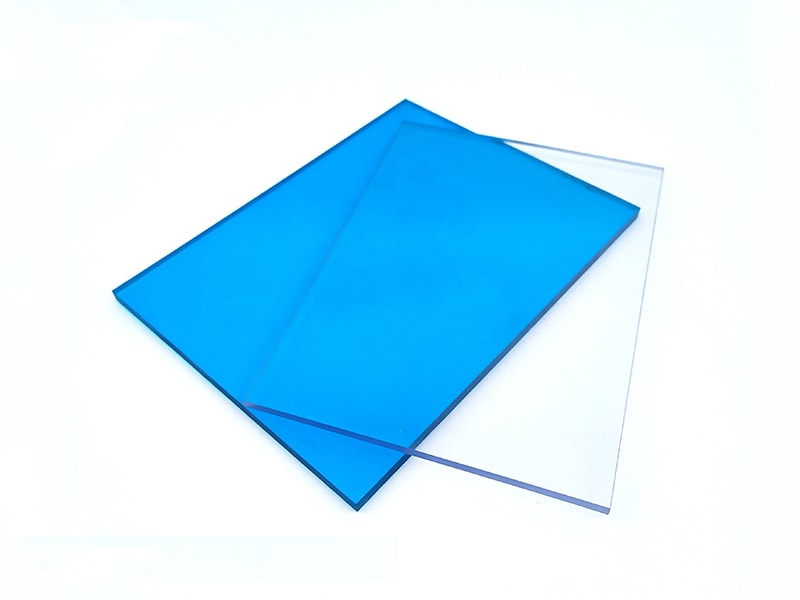

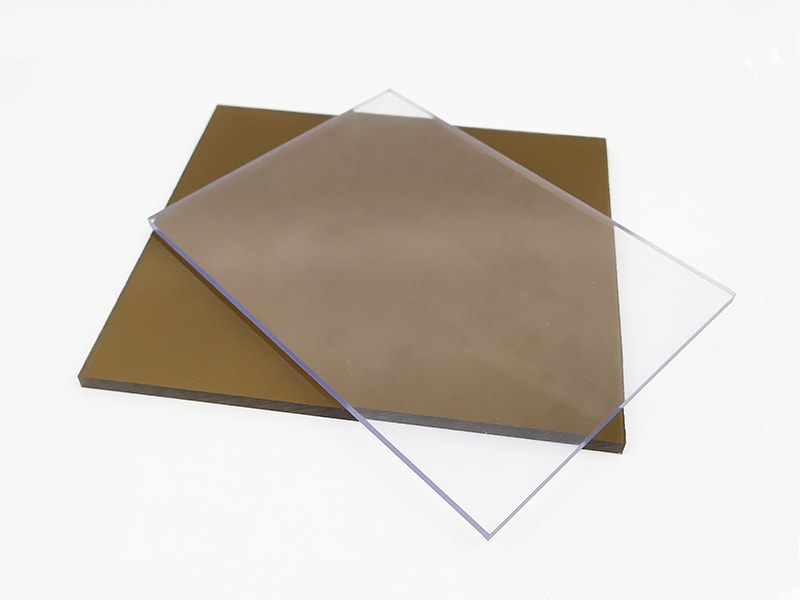

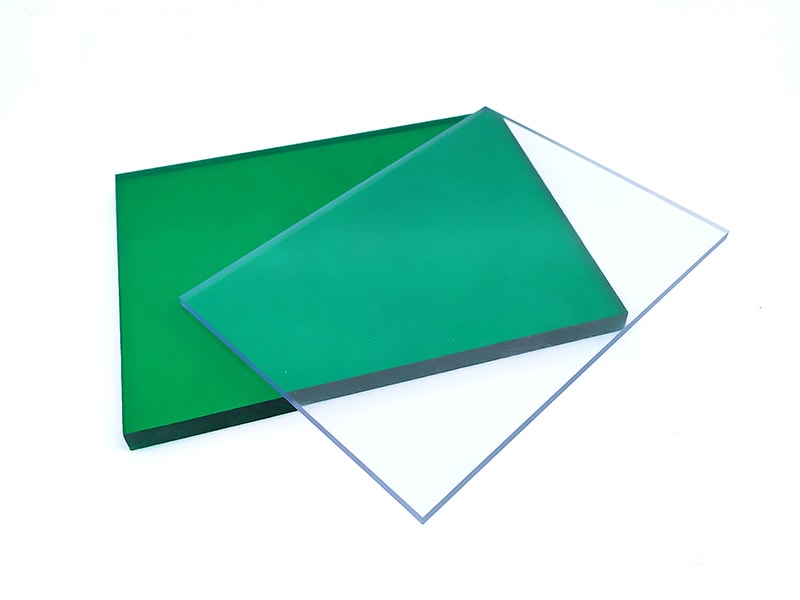

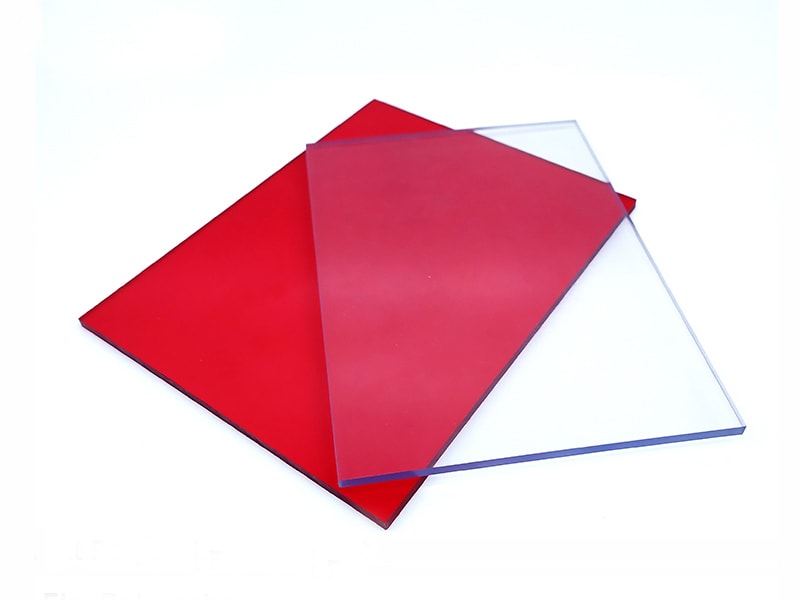

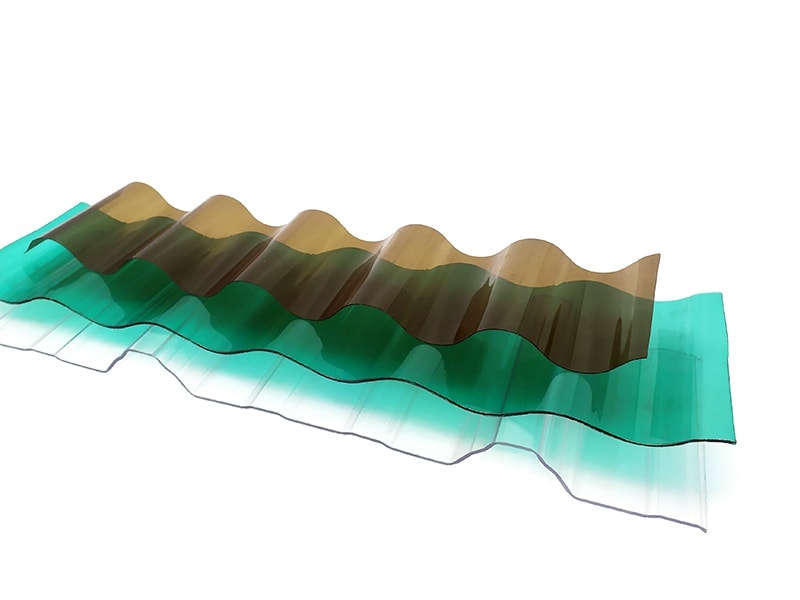

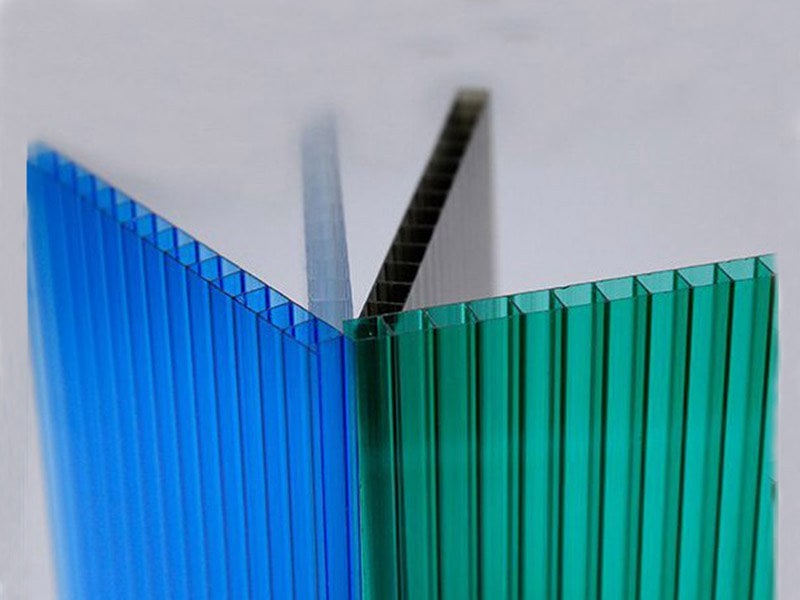

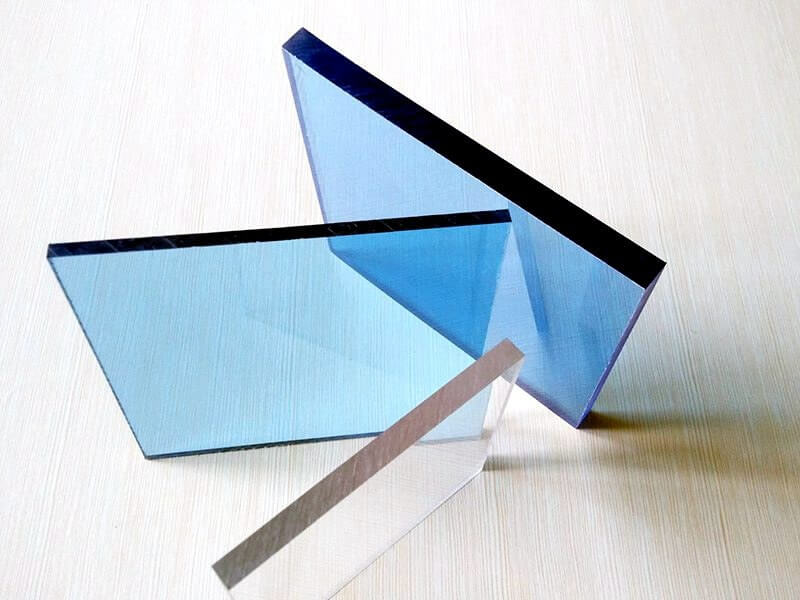

Products Color

| Type | Colors Description |

|---|---|

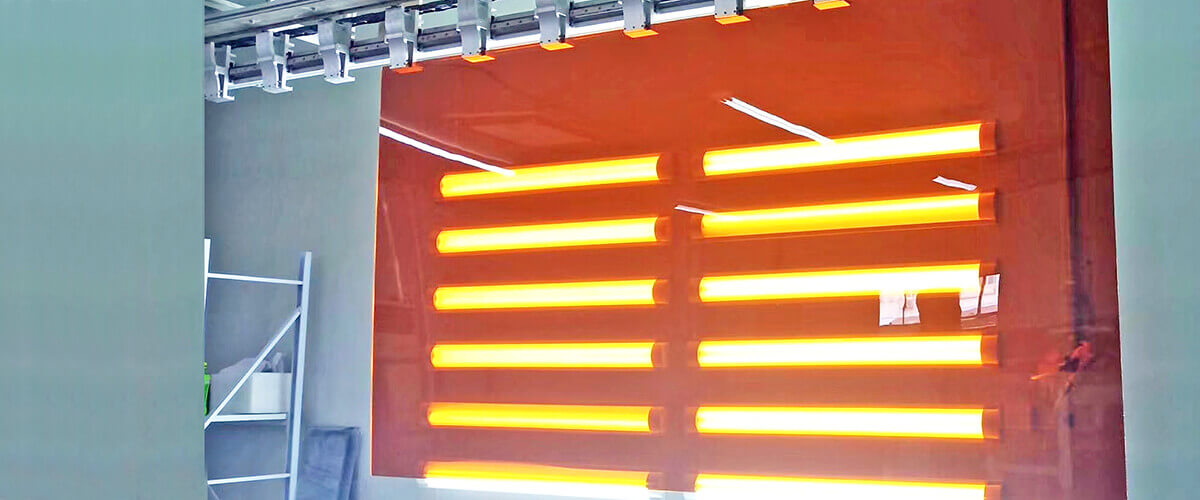

| Transparent | Clear, Brown, Bronze, Gary, Red, Blue, Lighter Blue, Green, Lighter Green |

| Translucent | Black, White Opal, White Diffuser, Yellow, Red, Mint Green, White Opal |

| Opaque | Black, White Opal, Yellow, Dark Blue, Red, Dark Grey, Dark Brown |